Which is designed and manufactured for use in water, waste water, and sewage. Main usage is for isolation purposes. Full bore design makes it possible to be used bi-directionally and the fluid could clean the sealing surface area every time the valve is opened.

Metal Seated Gate Valve operated with Spur gearbox and AUMA electric actuator

This type of Gate valve is in compliance with EN1171, DIN 3204 F4/BS 5163&EN558-1 series 3 designed for drink water, raw water, treated water, waste water, cooling water etc. and used as isolation valve.

Used as line valves to throttle and cut off the service fluid.

Typically used for water, TSE water/treated waste water and sea water services

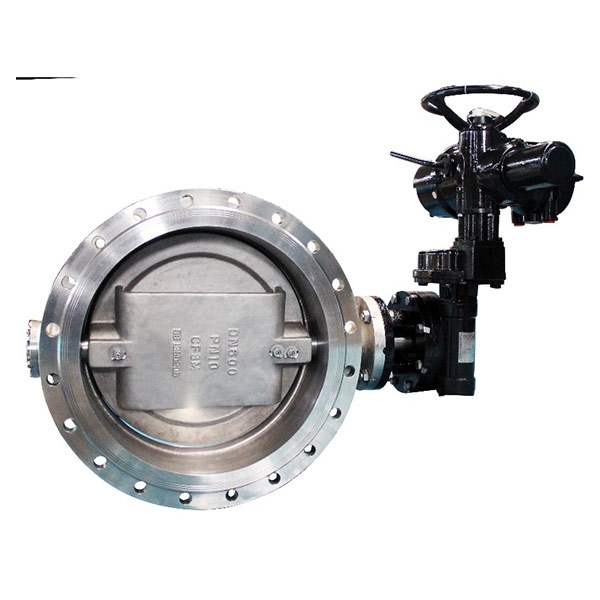

DOUBLE ECCENTRIC BUTTERFLY VALVE

With EN1074-1 & EN1074-2 type approval certification, For use with drinking water, WRAS approved

Rubber-Seated Butterfly Valves to AWWA C504, designed for drink water, sea water, cooling water etc. NSF/ANSI 61 approval is available.

Design is rated for B valves (max. flow velocity 16ft/sec-4.9m/sec), and absolutely compliance with the requirements in min. shaft diameter, min. body shell thickness and actuator test cycles, workshop testing and Proof-of-design tests etc.

BFV-02-QJ Rubber lined Butterfly Valve, internally with ebonite lining of thickness 3mm or 5mm.

The typical applications of this type of butterfly valves are chemical plants, sea water treatment, desalination projects, nuclear power plants, water treatment, TSE, sewage etc.

This kind of butterfly valve has the unique advantages:

– Keeping the main valve closed and bypass valve open. That can maintain minimum flow across the valve to avoid water stagnancy and maintain water quality.

– Equalize the pressure across the valve to enable manual opening in case of power unavailability.

Triple eccentric butterfly valve

Metal to metal hard seated face, or laminated seated

Product Features Standards Applications Product Dimension Related Products

Product Features Standards Applications Product Dimension Related Products

The eccentric semi ball valve has stable performance, quick and light opening, self-compensation for wear, reliable and durable sealing, easy adjustment and maintenance, straight through structure with large flow area and small damping, which can remove scale by itself, and is convenient for opening and closing. It is used to cut off, connect and adjust the medium in the pipeline.