The function of the telescopic device is to connect pumps, valves and pipes, and make compensation for them.

The pipe compensator can be extended axially within a certain range, and can also overcome the offset caused by different pipe axis at a certain Angle.

It greatly facilitates the installation and removal of valves and pipes. It can be freely extended among the permitted pipe extensions. Once it exceeds its expansion, it will exert limits to ensure safe operation of the pipe.

The telescopic device has a multi - direction displacement effect during pipeline operation. The pipes operate due to thermal expansion and contraction, and the subsidence and forces of the crust produce important scaling compensation effects.

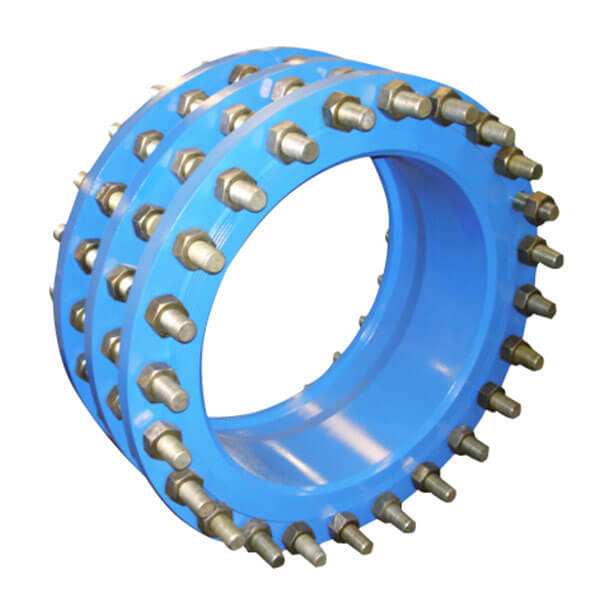

Dismantling Joint is assembled by a double flanged compositive fittings, acting a retractile action between a flanged spigot and a flange adaptor.

It designed to provide longitudinal adjustment (up to 50mm) in flanged systems. It provides a simple method for the installation and removal of flanged products by adjusting the distance between two flanged products and turning round.

The installation is also simple and only use a torque wrench to tighten the high strength steel or stainless-steel connecting bolts.

It can be quickly disassembled and very convenient for the repair & maintenance of the valves, pumps or instrumentation.

It simplifies the time required for maintenance and modification in future plumbing and reduces downtime for the entire pipeline project.

In all, the expansion joint provides great convenience for the installation and replacement of various water supply and drainage pipes, water towers, pumps, water meters and valves.

The product has a lot of regulating effect on the expansion and contraction caused by the temperature difference in the long pipeline transmission.

This kind of butterfly valve has the unique advantages:

– Keeping the main valve closed and bypass valve open. That can maintain minimum flow across the valve to avoid water stagnancy and maintain water quality.

– Equalize the pressure across the valve to enable manual opening in case of power unavailability.

BFV-02-QJ Rubber lined Butterfly Valve, internally with ebonite lining of thickness 3mm or 5mm.

The typical applications of this type of butterfly valves are chemical plants, sea water treatment, desalination projects, nuclear power plants, water treatment, TSE, sewage etc.

Rubber-Seated Butterfly Valves to AWWA C504, designed for drink water, sea water, cooling water etc. NSF/ANSI 61 approval is available.

Design is rated for B valves (max. flow velocity 16ft/sec-4.9m/sec), and absolutely compliance with the requirements in min. shaft diameter, min. body shell thickness and actuator test cycles, workshop testing and Proof-of-design tests etc.

Main Parts Material List Product Description The Function and Principle The function of the telescopic device is to connect pumps, valves and pipes, and make…