Which is designed and manufactured for use in water, waste water, and sewage. Main usage is for isolation purposes. Full bore design makes it possible to be used bi-directionally and the fluid could clean the sealing surface area every time the valve is opened.

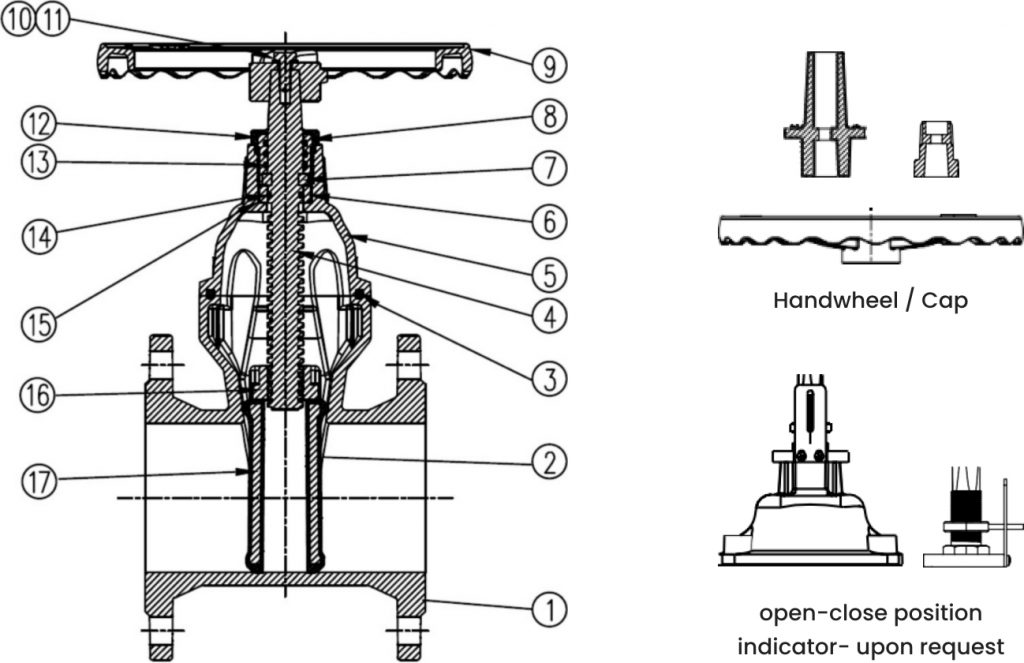

| No. | Component | Standard Material | Optional upon request |

| 1 | Body | Ductile Iron GJS 500-7 | Ductile Iron GJS 400-7 |

| 2 | Disc | Ductile Iron + EPDM | Ductile Iron + WRAS Approved EPDM |

| 3 | Bonnet Gasket | NBR | EPDM / WRAS Approved EPDM |

| 4 | Stem | Stainless Steel AISI 420 | AISI 431 / 304 / 316 / 316L / Duplex |

| 5 | Bonnet | Ductile Iron GJS 500-7 | Ductile Iron GJS 400-7 |

| 6 | Thrust Washer | Brass | Bronze / Dezincification Brass |

| 7 | Holding Ring | Brass | Bronze / Dezincification Brass |

| 8 | Thrust Nut | Brass | Bronze / Dezincification Brass |

| 9 | Handwheel / Cap | Ductile Iron GJS 500-7 | |

| 10 | Handwheel Bolt | Stainless Steel AISI 304 | Stainless Steel AISI 316 |

| 11 | Flat Washer | Stainless Steel AISI 304 | Stainless Steel AISI 316 |

| 12 | Dust Cover | NBR | EPDM / WRAS Approved EPDM |

| 13 | O-Ring | NBR | EPDM / WRAS Approved EPDM |

| 14 | O-Ring | NBR | EPDM / WRAS Approved EPDM |

| 15 | O-Ring | NBR | EPDM / WRAS Approved EPDM |

| 16 | Stem Nut | Brass | Bronze / Dezincification Brass |

| 17 | Disc Core | Ductile Iron GJS 500-7 | |

| 18 | Bonnet bolts | Galvanized carbon steel | Stainless Steel AISI 304 / 316 |

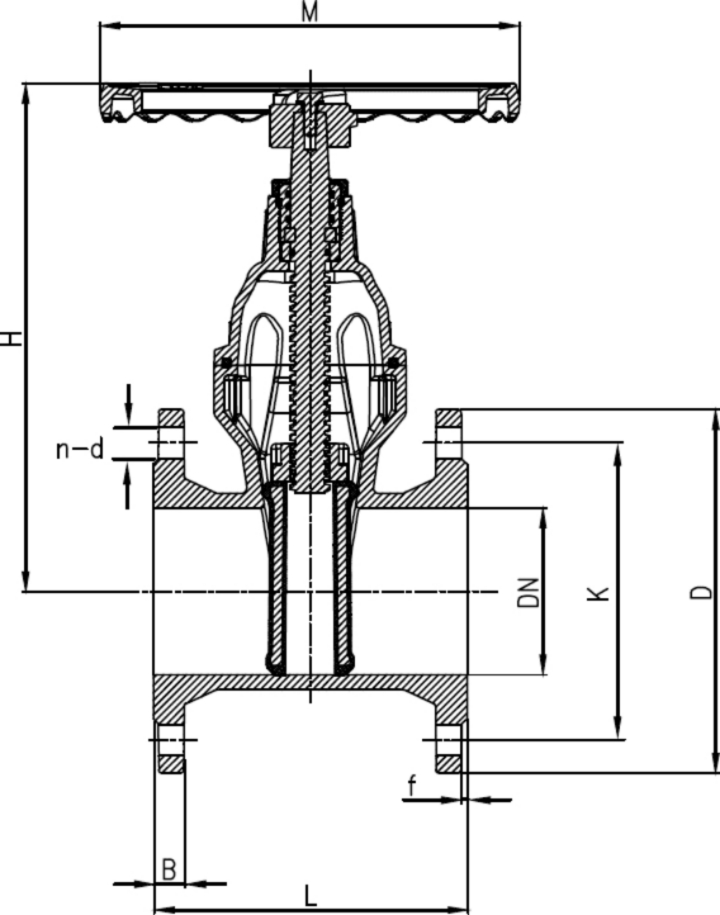

| SIZE | Outline (mm) | Flange dimensions (mm) | Switch Turns | Closing Torque (N.m) | |||||||||||||

| BS5163 | DIN-F4 | DIN-F5 | M | H | EN1092 - 2, PN10/16 | EN1092 - 2, PN25 | |||||||||||

| DN | L | D | K | n-d | B | f | D | K | n-d | B | f | ||||||

| DN40 | 165 | 140 | 240 | Φ200 | 215 | 150 | 110 | 4-φ19 | 19 | 3 | 150 | 110 | 4-φ19 | 19 | 3 | 9 | 30 |

| DN50 | 178 | 150 | 250 | Φ200 | 215 | 165 | 125 | 4-φ19 | 19 | 3 | 165 | 125 | 4-φ19 | 19 | 3 | 9 | 40 |

| DN65 | 190 | 170 | 270 | Φ200 | 250 | 185 | 145 | 4-φ19 | 19 | 3 | 185 | 145 | 8-φ19 | 19 | 3 | 10 | 50 |

| DN80 | 203 | 180 | 280 | Φ200 | 275 | 200 | 160 | 8-φ19 | 19 | 3 | 200 | 160 | 8-φ19 | 19 | 3 | 12 | 60 |

| DN100 | 229 | 190 | 300 | Φ254 | 320 | 220 | 180 | 8-φ19 | 19 | 3 | 235 | 190 | 8-φ23 | 19 | 3 | 12 | 80 |

| DN125 | 254 | 200 | 325 | Φ315 | 365 | 250 | 210 | 8-φ19 | 19 | 3 | 270 | 220 | 8-φ28 | 19 | 3 | 14.5 | 100 |

| DN150 | 267 | 210 | 350 | Φ315 | 400 | 285 | 240 | 8-φ23 | 19 | 3 | 300 | 250 | 8-φ28 | 20 | 3 | 17 | 120 |

| DN200 | 292 | 230 | 400 | Φ315 | 495 | 200 | 160 | 8-φ23/12-φ23 | 20 | 3 | 360 | 310 | 12-φ28 | 22 | 3 | 18.5 | 150 |

| DN250 | 330 | 250 | 450 | Φ406 | 590 | 220 | 180 | 12-φ23/12-φ28 | 22 | 3 | 425 | 370 | 12-φ31 | 24.5 | 3 | 23 | 200 |

| DN300 | 356 | 270 | 500 | Φ406 | 670 | 250 | 210 | 12-φ23/12-φ28 | 24.5 | 4 | 485 | 430 | 16-φ31 | 27.5 | 4 | 27 | 250 |

This kind of butterfly valve has the unique advantages:

– Keeping the main valve closed and bypass valve open. That can maintain minimum flow across the valve to avoid water stagnancy and maintain water quality.

– Equalize the pressure across the valve to enable manual opening in case of power unavailability.

BFV-02-QJ Rubber lined Butterfly Valve, internally with ebonite lining of thickness 3mm or 5mm.

The typical applications of this type of butterfly valves are chemical plants, sea water treatment, desalination projects, nuclear power plants, water treatment, TSE, sewage etc.

Rubber-Seated Butterfly Valves to AWWA C504, designed for drink water, sea water, cooling water etc. NSF/ANSI 61 approval is available.

Design is rated for B valves (max. flow velocity 16ft/sec-4.9m/sec), and absolutely compliance with the requirements in min. shaft diameter, min. body shell thickness and actuator test cycles, workshop testing and Proof-of-design tests etc.

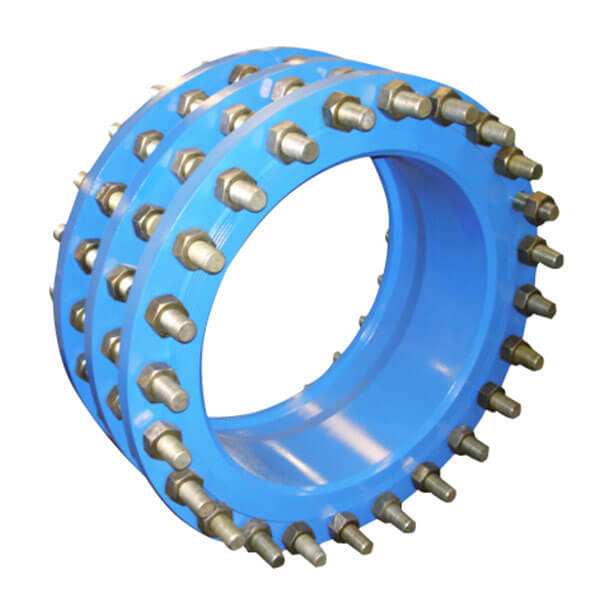

Main Parts Material List Product Description The Function and Principle The function of the telescopic device is to connect pumps, valves and pipes, and make…